Manufacturing outsourcing

Given current geopolitical, economic and demographic (health) uncertainties companies that want to survive on the market today need to focus on their core skills. Outsourcing non-core manufacturing and / or assembly capacities outside of the company is a key solution for optimisation and a path to a lean entity. BULDE has the capacity to provide original equipment manufacturers with full outsourcing of component manufacturing and assembly services.

Focusing on core skills

Outsourcing makes a company more efficient, because freed-up management and labour capacity can be redirected into the most valuе-added products/segments of a company. Relying on contract manufacturing (outsourcing) provides opportunities for re-organisation of the labour force, re-thinking of organizational structure as well as layout optimisations. It is particularly important in tough economic times that the management team can focus entirely on strategic decisions. A strong external manufacturing partner ensures timeliness and quality of supply. The latter combined with direct sourcing of raw material by BULDE frees up space in Procurement force as well as Logistic area. See Sections Procurement and Warehousing.

Experience

Taking over and continuing production/assembly with machinery and personnel requires vast experience and expertise. Over the past decade, BULDE management has successfully completed numerous outsourcing projects for multinationals and is continuing to enhance in this realm.Protecting the intellectual property of the customer is always an absolute top priority throughout this process.

- Productivity & Scrap Analysis

- Cost of Quality Analysis

- 5S / Kaizen implementation

- Down-time analysis

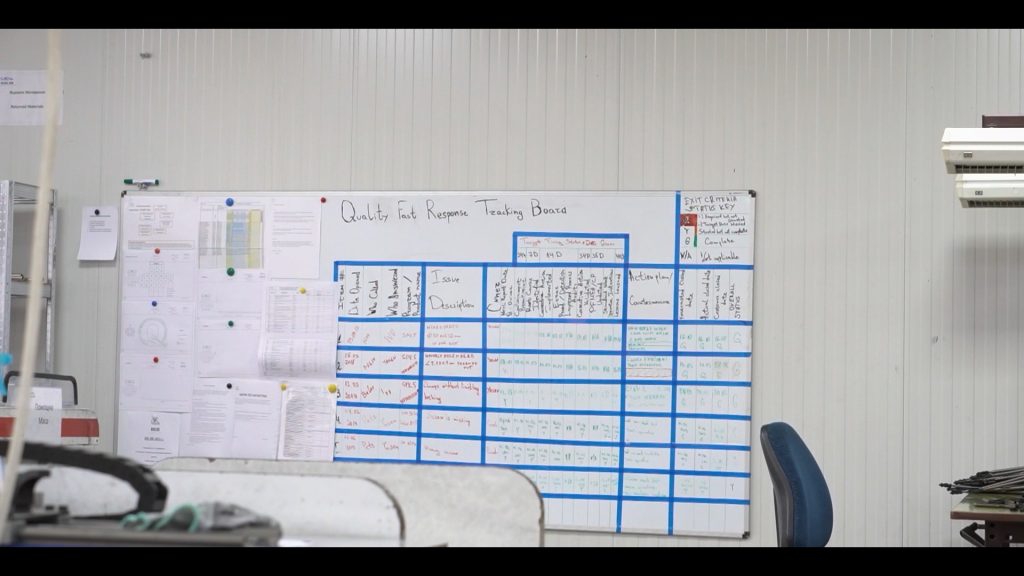

- Quiality Fast Response Tracking Board